Technology: Ultra and Super Plus Platforms

Mechanical Impedance Matching: How It Works

(and why you should care!)

Click image for larger picture

Overview

Like the Super Plus platform, the Ultra's construction consists of numerous layers of materials arranged in a specific order. These layers are arranged in a special order - from an aluminum outer skin to a foam center, and back again - for a purpose.

Getting Rid of Vibrational Energy

The laws of physics in the early part of the 21st century dictate, as they did in Newton's time, that there are only two ways to get rid of energy: use it up as work, or dissipate it as heat. In the case of our platforms, we attempt to realize the second method (Rollerblocks work primarily on the first principle). If mechanical energy flows in a very lossy material, it can be dissipated as heat. The foam center of the Ultra is ideal for this purpose. However, coaxing the energy into this foam center isn't as easy as it might seem.

What's Wrong With the Concept of "Isolation"

"Isolation" is a much-used term to describe the effects of various feet, pucks, shelves, platforms, and other accessories used to enhance the performance of audio and video systems. However, isolation alone isn't the answer, but only part of the answer. Isolation keeps additional vibration from entering a component- but does nothing to drain a component of inborne vibrational energy, such as that from transformers, spinning disc motors, sound waves traveling through the air, and even from high energy devices like transistors and diodes, which often vibrate or "sing" as their junctions heat and cool with the high current densities flowing across them. This energy, circulating in the component, is actually more significant than energy which comes from the supporting surface, which is all that a perfect "isolation" device can treat. These devices, most often using single or multiple air bags, and do a reasonably good job (when designed correctly- and that's expensive to do!) at "cutting off" a component from the outside world- and in the process, completely trap existing energy in the component. In order for optimum vibration control treatment of a component, both isolation and drainage must be provided.

Leading the Horse to Water, and Making Him Drink "Isolation" is a much-used term to describe the effects of various feet, pucks, shelves, platforms, and other accessories used to enhance the performance of audio and video systems. However, isolation alone isn't the answer, but only part of the answer. Isolation keeps additional vibration from entering a component- but does nothing to drain a component of inborne vibrational energy, such as that from transformers, spinning disc motors, sound waves traveling through the air, and even from high energy devices like transistors and diodes, which often vibrate or "sing" as their junctions heat and cool with the high current densities flowing across them. This energy, circulating in the component, is actually more significant than energy which comes from the supporting surface, which is all that a perfect "isolation" device can treat. These devices, most often using single or multiple air bags, and do a reasonably good job (when designed correctly- and that's expensive to do!) at "cutting off" a component from the outside world- and in the process, completely trap existing energy in the component. In order for optimum vibration control treatment of a component, both isolation and drainage must be provided.

Leading the Horse to Water, and Making Him Drink

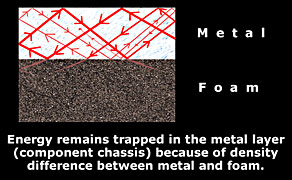

Energy that is flowing in a given material tends to remain in that material, and tends to refect from the boundaries into a different material. Vibration in, for instance, a metal bar, will tend to circulate inside it (see picture above). The energy will not cross the boundary between the metal bar and air very easily; it will tend to bounce off the interior walls and keep "reflecting" inside the metal bar, like a ricocheting bullet bouncing off the walls of a cave, until it finally runs out of energy and dies out - which can be a relatively long time, since metal is not very "lossy," which means it can support energy transmission with low loss. By comparison, the same energy in a highly absorptive thermal foam material will be "killed" very quickly as it is converted to heat. But the difference between the density of metal and the density of the foam is very different, and most of the energy does not cross the boundary into the foam. It stays in the metal; a very small percentage of the energy gets through. In effect, the foam is not there.

Mechanical Impedance Matching

The problem we have here is basically one of matching impedances of different materials. Metals present a different impedance to energy than foam; to bridge the gulf, we need something to coax it across.

The Mediator

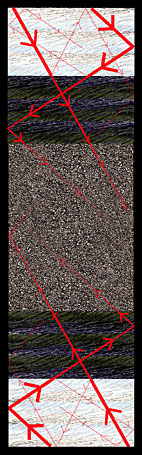

By putting a material in between two dissimilar materials with an impedance that's roughly halfway between them, we can increase the amount of transmission across the gulf. Energy wouldn't cross from metal to foam directly, but more of it will cross from metal to a mediating dense wood layer. It's rougly equivalent to the idea of climbing very high steps: it takes a lot of muscle power to climb steps that are, say, 3 feet high, but it's much easier to climb steps that are only 6 inches high. Splitting up the distance into smaller steps that are easier to climb is much like the idea of putting mediating layers between the metal and the foam. It's easier for the energy to "climb" the varying steps between them than to make the great jump all in one leap! There still is some reflection (represented in the illustrations as smaller arrows reflecting at boundaries), but overall, much more energy is able to penetrate, thus getting more of it away from the component. The Ultra's and Super Plus's patented design thus achieves a degree of "impedance matching" between most equipment chassis, which are usually metallic, and its center foam section, whose purpose it is to convert mechanical energy into heat.

Achieving Isolation with Drainage

As shown at right, Symposium Ultra and Super Plus platforms utilize mediating "impedance matching" sections to coax more energy out of the component and into the dissipative layers where it can be harmless dissipated as heat. One of the unique facets of our design is its symmetrical construction: the same ordered-density layering occurs not just from top to foam section, but also from the bottom. This means that the bottom of the platform "damps" or dissipates vibrational energies which come from the support structure- be it a rack, a shelf, floor, or a set of cones, etc. Since energy is dissipated from this direction as well, a degree of true isolation- without the "bounce" or other problems introduced by air bags- is achieved. This is why most people comment on the superb midbass reproduction realized with Symposium platforms- because this is the region where most air bag systems fail, because they "ring" due to the storage and release characteristics of the rubber used in common air bags, which are little more than small bicycle tires.

Constrained-Layer Damping: Additional Benefits of Bonding Adjacent Layers As shown at right, Symposium Ultra and Super Plus platforms utilize mediating "impedance matching" sections to coax more energy out of the component and into the dissipative layers where it can be harmless dissipated as heat. One of the unique facets of our design is its symmetrical construction: the same ordered-density layering occurs not just from top to foam section, but also from the bottom. This means that the bottom of the platform "damps" or dissipates vibrational energies which come from the support structure- be it a rack, a shelf, floor, or a set of cones, etc. Since energy is dissipated from this direction as well, a degree of true isolation- without the "bounce" or other problems introduced by air bags- is achieved. This is why most people comment on the superb midbass reproduction realized with Symposium platforms- because this is the region where most air bag systems fail, because they "ring" due to the storage and release characteristics of the rubber used in common air bags, which are little more than small bicycle tires.

Constrained-Layer Damping: Additional Benefits of Bonding Adjacent Layers

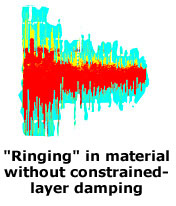

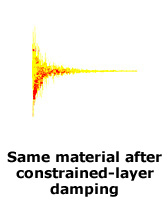

As each Symposium layer is intimately bonded to the next with an extremely thin and uniform adhesive layer, it effectively achieves constrained-layer damping of each layer. Constrained-layer damping eliminates the resonance each layer would normally have and renders the combination far more neutral and resonance-free than either layer would be by itself. Each of the 11 "step" layers in the Ultra is bonded to its adjacent layer; these change, in gradual steps, from a fast transmission material with very good thermal and mechanical transmission characteristics(aluminum)to its foam center, which has very poor mechanical transmission and excellent loss characteristics, and then back again(going from top to bottom, or reverse). In this way, mechanical energy can be absorbed and dissipated as heat. Constrain-layering the various strata ensures that spurious, secondary resonances are kept to a minimum.

How This Affects the Performance of Your Components As each Symposium layer is intimately bonded to the next with an extremely thin and uniform adhesive layer, it effectively achieves constrained-layer damping of each layer. Constrained-layer damping eliminates the resonance each layer would normally have and renders the combination far more neutral and resonance-free than either layer would be by itself. Each of the 11 "step" layers in the Ultra is bonded to its adjacent layer; these change, in gradual steps, from a fast transmission material with very good thermal and mechanical transmission characteristics(aluminum)to its foam center, which has very poor mechanical transmission and excellent loss characteristics, and then back again(going from top to bottom, or reverse). In this way, mechanical energy can be absorbed and dissipated as heat. Constrain-layering the various strata ensures that spurious, secondary resonances are kept to a minimum.

How This Affects the Performance of Your Components

When noise is reduced in the component, and isn't reflected back (which is what usually happens with support structures that don't have dissipative ability), there's less noise in the component, and less induced electrical noise in the circuitry,which produces less intermodulation distortion. In addition, other forms of low-level distortions are reduced, making music sound more like it should: sweeter, more relaxed, and ultimately, more natural, but still retaining its exciting qualities: tighter, more dynamic, and ultimately, more engaging.

Copyright © 2002 Symposium USA, Inc. All Rights Reserved

|

"Isolation" is a much-used term to describe the effects of various feet, pucks, shelves, platforms, and other accessories used to enhance the performance of audio and video systems. However, isolation alone isn't the answer, but only part of the answer. Isolation keeps additional vibration from entering a component- but does nothing to drain a component of inborne vibrational energy, such as that from transformers, spinning disc motors, sound waves traveling through the air, and even from high energy devices like transistors and diodes, which often vibrate or "sing" as their junctions heat and cool with the high current densities flowing across them. This energy, circulating in the component, is actually more significant than energy which comes from the supporting surface, which is all that a perfect "isolation" device can treat. These devices, most often using single or multiple air bags, and do a reasonably good job (when designed correctly- and that's expensive to do!) at "cutting off" a component from the outside world- and in the process, completely trap existing energy in the component. In order for optimum vibration control treatment of a component, both isolation and drainage must be provided.

As shown at right, Symposium Ultra and Super Plus platforms utilize mediating "impedance matching" sections to coax more energy out of the component and into the dissipative layers where it can be harmless dissipated as heat. One of the unique facets of our design is its symmetrical construction: the same ordered-density layering occurs not just from top to foam section, but also from the bottom. This means that the bottom of the platform "damps" or dissipates vibrational energies which come from the support structure- be it a rack, a shelf, floor, or a set of cones, etc. Since energy is dissipated from this direction as well, a degree of true isolation- without the "bounce" or other problems introduced by air bags- is achieved. This is why most people comment on the superb midbass reproduction realized with Symposium platforms- because this is the region where most air bag systems fail, because they "ring" due to the storage and release characteristics of the rubber used in common air bags, which are little more than small bicycle tires. Constrained-Layer Damping: Additional Benefits of Bonding Adjacent Layers

As each Symposium layer is intimately bonded to the next with an extremely thin and uniform adhesive layer, it effectively achieves constrained-layer damping of each layer. Constrained-layer damping eliminates the resonance each layer would normally have and renders the combination far more neutral and resonance-free than either layer would be by itself. Each of the 11 "step" layers in the Ultra is bonded to its adjacent layer; these change, in gradual steps, from a fast transmission material with very good thermal and mechanical transmission characteristics(aluminum)to its foam center, which has very poor mechanical transmission and excellent loss characteristics, and then back again(going from top to bottom, or reverse). In this way, mechanical energy can be absorbed and dissipated as heat. Constrain-layering the various strata ensures that spurious, secondary resonances are kept to a minimum.