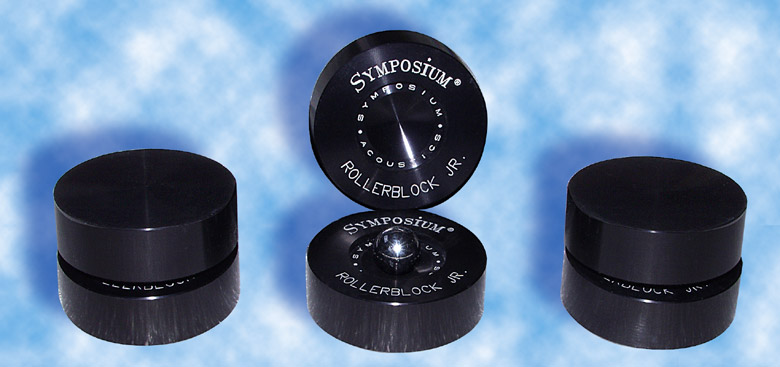

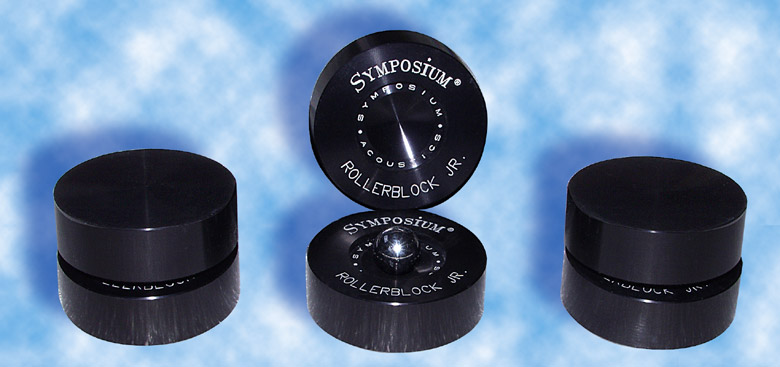

ROLLERBLOCK® JR.

"Son" of Rollerblock!

Rollerblock Jr. improves resolution and lowers distortion with audio components, AC power devices, loudspeakers, and more

ROLLERBLOCK® JR.

"Son" of Rollerblock!

Rollerblock Jr. improves resolution and lowers distortion with audio components, AC power devices, loudspeakers, and more

"The rollerblock jr. w/ tungsten is incredible. It's hard to believe that they can make such a huge difference, but they certainly do. I placed them under my dvd/sacd/cd player and the soundstage blew me away... Thanks again."

- L.R., New Jersey

"Just wanted you to know that I started by just using the Rollerblock Jr's under the Oppo 95 universal player. Was interested to see what they could do on their own. And what they did was a very pleasant surprise, indeed. While the improvement is sound was both obvious and substantial, it was the improvement in PQ that just about knocked me over!! I thought I had a great picture on my 60" Panasonic Plasma before. But, using Rollerblock Jr's took it up a couple more notches ...at least! Quite frankly, I was amazed and delighted with the improvements Rollerblock Jr's gave.

...Anyway, there you have it. Another super satisfied customer to add to your long list."

- B.T.

"...They look very well engineered and are of very good workmanship. Well done... Adding rollerblocks to my system has improved further the level of detail and the total stereo picture has become more true and musically involving."

- A.K., Netherlands

"Just got the Rollerblock Jr. and they blow away the Aurios I've been using under my SET amp...the highs are cleaner, the lows are fuller and articulated, the staging is deeper and wider but above all there is no interference in the pace and rhythm, they are much more fluid, open, bigger sounding...Thank you..."

R.G., New York City

"...just to let you know I got the Rollerblock Jrs... I put them on the turntable, on the motor board... They're unbelievable, the sound is UN-Believable. Detail, soundstage, and the motor noise is diminished to where you really, really have to listen hard, just to be aware of it. Excellent, excellent. Thanks again..."

- R. W., New Jersey

"...after i tried the platform and Rollerblocks jr under my Rega Planet i just have to say WWOOOWWWW !!! It sounds like another player, it just lost all the nasties associated with digital, now the highs have detail but lost the "bite" and sound sweeter than before, the sound overall is more balanced and has more "air" and the bass is even and lost the boom and sounds more natural and articulated with the rest. Guys you just made it!!... Thank you very much, you have my appreciation."

Yours in music, M.F., Portugal

Introduction

has been the standard of excellence for ball bearing isolation in the high end audio industry. Many rave reviews and customer comments reinforced their position as the premier ball bearing isolation device. However, it became evident that there was a need for a lower cost "introductory" ball bearing isolation device designed with the same audio expertise and commitment to quality as the original Rollerblock. Thus, Rollerblock Jr. became a reality.

Symposium introduced lateral ball bearing isolation with the original Rollerblock® in 1997; since then, Symposium's Rollerblock® Series 2Description

Rollerblock Jr. consists of of 6 tops and bottoms and 3 center bearings, to make 3 "Double Stacked" or sandwiched isolator/coupler units. Each top and bottom is constructed of black anodized, aircraft alloy aluminum, and has a 1.875" diameter (4.76 cm) and 5/8" (1.58 cm) thickness. These dimensions were carefully chosen to make Rollerblock Jr. easy to use and set up, yet strong enough to withstand the rigors of use under heavier equipment such as large amplifiers and heavy loudspeakers. The special cup interior has been designed so that the top and bottom "sandwich" is stable with the ball inserted in the center, making for easy setup. The bottom and top are flat and suitable for all equipment chassis as well as flat surfaces and carpeting (including deep pile carpets).Version 1.1

After its first production run, Rollerblock Jr. was modified to include a 1/4-20 threaded hole dead center on the opposite face from the cup. This threaded hole allows the Rollerblock Jr. body to be screw-mounted to many existing equipment foot fastener systems, and facilitates secure fastening to Symposium Precision Couplers (this allows making an effectively thicker [1.625" or 4.1 cm] Rollerblock Jr. for clearing extremely high equipment feet, or other applications) or with "hanger bolts" for securing into wood platforms, etc. Also, the alloy material of the blocks was upgraded to a higher grade aircraft aluminum. Cup sphericity and all other geometric relationships were maintained.Ball bearings

Standard Rollerblock Jr. is supplied with Grade 25 chromium steel balls as standard. Super-precision Grade 10 Tungsten Carbide balls are available as an optional upgrade; this configuration is "Rollerblock JR+", the "+" signifying that Tungsten bearings are included.Weight Capacity

Genuine Rollerblock JR will easily handle 50 pounds per unit and more; thus a set of 3 has a conservative load capacity of 150 pounds (70 kG). A set of 4 will handle 200 pounds (90 kG). NOTE: Beware of counterfeit units, which will be damaged if used with high weights because of the inferior materials used in their manufacture! For very high weight loads or extremely heavy loudspeakers, we recommend the use of Rollerblock JR HDSE. The "HDSE" stands for "Heavy Duty Special Edition," and HDSE sets will handle double or triple the weight load of standard Rollerblock JR, with enhanced resolution and bass rendering. Please click here for more information on HDSE.Application

Rollerblock Jr. is effective with virtually all components, especially digital sources (CD players and transports), preamplifiers, and amplifiers, but can also be used to isolate and couple entire shelves and platforms, turntables, power supplies (including AC "line conditioners") and loudspeakers.

Rollerblocks used under a large VPI turntable, and coupled together with Precision Couplers for added height.

Please CLICK ON IMAGE for larger picture.

Under Loudspeakers

Rollerblock JR is very effective (and safe to use!) with all types of loudspeakers, including planar dynamic types (Magneplanar, Electrostatic, etc) as well as conventional "box" speakers. They work on ALL types of flooring, including deep pile carpeting. They are also particularly effective with subwoofers, since the Rollerblock "slip plate" principle "disconnects" the woofer from the returning bass wave "echo" that eventually propagates through walls and floor back to the woofer itself. This returning echo creates intermodulation distortion by shaking the woofer and creating phase and response anomalies which damage bass reproduction quality.

"...I have a small 16' x 11' x 10' dedicated listening room, lots of amp power (McIntosh mono's) driving standmount Sonus Faber Guarneri Evolutions paired with two large REL Gibraltar 2 sub woofers...even just kind of idling along I've struggled with the subs at times....weird, just on certain tracts I'd get this underlying bass that would sound like a small train rumbling near by...again, really just on certain cuts...weird part is even on albums that the sound engineer obviously over emphasized the bass (Patricia Barbers' Modern Cool comes to mind) it would be just fine, sound awesome....then one tract on Diana Kralls new CD would create this overload....and not really any heavy bass going on so obviously some very deep underlying bass frequency....I tried positioning the RELs all over hell and gone but just couldn't get rid of it....the room is heavily treated by the way...out of desperation I thought I'd try some unused, older Rollerblocks jrs I had and this really has turned it! Bass is much more defined and any sense of "boominess" is gone! This goes against what the REL guys suggest....they in fact recommended simple Bluetak between the feet and my stone floor.....sounded like crap."

- P. R., Arizona

Sonic Benefits

Proper installation results in increased transparency, dynamics and musicality, properties which include better harmonic separation and reduction of vibration-produced excessive sibilance. Further, one may expect to discern greater clarity between instruments in the sonic field, and better defined bass performance with more accurate timbral balance.Theory of Operation

The purpose of a ball bearing isolation device is to laterally isolate a component from external mechanical waves (vibration) without inducing additional colorations or distortions (which can be induced through poor choice of materials, which in turn may resonate or vibrate, inducing new distortions in the component being treated). While it may seem that any sort of ball-and-race bearing will do (such as "marbles and spoons"), proper execution requires care and precision. The careful engineering of the problem is the difference between a "toy" and an essential component, and if not done correctly, will create new problems.Rollerblock Jr.'s virtues, like the original Rollerblock Series 2, are subtractive in nature. That is, rather than attempting to compensate for an existing problem or deficiency in a system through the introduction of new resonance, Rollerblock Jr. is designed (as are all Symposium products) to remove the cause of resonance and distortion. Footer devices and accessories should not create another problem by adding a new resonance; many will thicken bass and lower midrange with artificial bass overhang, lending a false "warmth" and impression of superior bass, which eventually becomes fatiguing, damaging timber accuracy and transient response of the entire music system. Still other devices using captured ceramic balls create a false sense of increased resolution by "spotlighting" the upper midrange area. This is simply distortion, and also can eventually result in listening fatigue.

A Few of the Problems - and their Solutions

All bearings create noise, called chatter, as they roll upon a surface. This noise is directly transferred into the component, and can become a secondary source of distortion. If chatter is not adequately reduced, the "cure" can become worse than the "disease." Devices which use more than one ball induce more noise than devices with fewer balls, all things being equal. Accordingly, Rollerblock Jr., like all Rollerblock devices, use the fewest number of balls possible - one per device - to ensure the lowest possible chatter. Further, not only is the ratio of the ball diameter to the cup critical for the best compromise between mechanical stability and performance, but so is the absolute size of these elements. Symposium pioneered the lateral plane ball bearing device for use with active components; since 1996 we have experimented with many different combinations and found that a 1/2" ball with our standard cup sphericity offers the best solution for real-world performance. Many positive reviews, thousands of units sold, and a virtual avalanche of positive responses from owners seem to confirm these findings.For this reason, Rollerblock Jr. employs the same basic ball and cup relationship of the Series 2+ Rollerblock. Experiments with different cup sphericities and ball materials have suggested that while different resonant conditions may be created, lateral isolation performance is no better, and in most cases, worse.

Technical Discussion

For a further technical discussion of the theory behind ball bearing isolation devices, please click here.

Rollerblock Jr. uses two cups of similar sphericity, positioned in opposition to each other, with a single ball in between. This "double stack" design was invented and first described by Symposium in our original patent on the Rollerblock, which was filed in 1997 and predates all descriptions of similar "DIY" ("Do It Yourself") audio isolation devices, as well as the many imitation ball and cup devices marketed by various competitors by several years. The use of a carefully chosen cup bearing, as opposed to a flat surface race, has several advantages when operated without external force fields to damp ball motion. (Note: Symposium was granted a patent for a magnetic bearing bias and stabilization in which a magnet is used to stabilize, center and provide frictionless resistance to ball bearing displacement. At present, this technology is employed in the Symposium Osiris Rack, and will be used in future Rollerblock systems.)Materials Choices and Mechanical Drainage

The material used in the Rollerblock body is critical to non-resonant, neutral performance: Rollerblock Jr.'s robust aircraft alloy construction resists inherent resonance and allows efficient drainage of spurious mechanical energy out of the component through itself to mechanical "ground" (in other words, the support surface) because aluminum has very high . This technique reduces the level of "mechanical voltage" in the component treated and this reduces inherent resonances and all forms of attendant intermodulation distortions caused thereby. Aluminum alloy was chosen for a specific reason: it is better as a coupling medium than brass, steels, ceramics, polymers, woods or other materials because of its superior mechanical transmission speed which is bettered in nature only by two other metals, silver and copper. Aircraft aluminum's excellent machinability, strength, hardness, general resistance to corrosion and reasonable cost make it a best choice as a mediating element, that is, as a bridge between one place and another, those two places being, in this discussion, a component and a mechanical ground.Similarly, listening tests in different systems with various components confirmed that Tungsten Carbide was the best ball bearing material. While many might assume that this is due to Tungsten Carbide's extreme hardness, Tungsten Carbide's excellent mechanical transmission qualities, which are close to aluminum, make it a better "match" to aluminum alloy and thus a much better choice than ceramic balls (which have slightly greater hardness but less desirable transmission characteristics which can create an artificial sense of "brightness") for preserving mechanical transmissivity through the entire Rollerblock structure, a primary design consideration.

The HDSE Version

. The HDSE version provides greater performance due to the superior characteristics of its 7075 alloy body and "hard coat" anodized skin. Supplied with High Precision Grade 10 Tungsten Carbide balls as standard (same standard ball quality as Series 2+), is recommended for critical components and is especially suited for use with extremely heavy loudspeakers and components. Please click here for more detailed information on Rollerblock Jr. HDSE.

Introduced in 2009: Rollerblock JR HDSE, a high-performance Rollerblock Jr. edition designed originally for the Panorama LoudspeakerOur Guarantee

As with all Symposium products, Rollerblock Jr. is made in the USA. We're very proud of its unmatched quality and precision, as well as its rock-solid and simple-to-use design. If dynamic, engaging, and musically truthful performance is the keynote of your goal in an audio or home theater system, we are confident that you will find that Rollerblock Jr. will outperform devices at several times its price, and "open" up your existing system - or the system you will own years from now - to a new and greater level of enjoyment.Purchasing Rollerblock Jr.

Dealers page for an official list of Canadian and overseas dealers, and call or email Symposium direct for a local dealer in the United States.

Rollerblock Jr. is sold factory direct and also through factory authorized, select dealers. Please consult ourWARNING! Beware of counterfeits which have been offered for sale on the used market. While similar in outward appearance, these fakes consist of markedly inferior materials, anodizing, machining and ball bearing quality, and will NOT perform to the same standards as genuine Symposium Rollerblocks. If you are in doubt or would like assistance in determining authenticity, please call or email us for more information.