Although Symposium Platforms will improve the performance of equipment with rubber or sorbothane feet, optimal results will result if these rubber or sorbothane footers are bypassed with hard footers, and especially footers made of solid metal. Why is this? The footer acts as a transitional device between two media: one medium being the component you are treating, such as an amplifier, source component, etc., and the neighboring medium, which in this case is the shelf, floor, or platform. Isolation is not the only aspect of vibration control which needs to be addressed; vibration control consists of two disciplines, one being isolation, and the other and usually more important aspect being energy drainage, also called resonance damping. Thus, it is important to ensure an efficient connection between the component chassis itself and the the platform or shelf upon which it is placed, so that good resonance damping and drainage of mechanical vibration out of the component may be realized. This is accomplished by ensuring that the footers between the component and the platform are good conductors of mechanical energy - otherwise known as vibration - so that this vibration can escape the component and be conducted into the platform, where it can be eliminated or conducted away.

Although Symposium Platforms will improve the performance of equipment with rubber or sorbothane feet, optimal results will result if these rubber or sorbothane footers are bypassed with hard footers, and especially footers made of solid metal. Why is this? The footer acts as a transitional device between two media: one medium being the component you are treating, such as an amplifier, source component, etc., and the neighboring medium, which in this case is the shelf, floor, or platform. Isolation is not the only aspect of vibration control which needs to be addressed; vibration control consists of two disciplines, one being isolation, and the other and usually more important aspect being energy drainage, also called resonance damping. Thus, it is important to ensure an efficient connection between the component chassis itself and the the platform or shelf upon which it is placed, so that good resonance damping and drainage of mechanical vibration out of the component may be realized. This is accomplished by ensuring that the footers between the component and the platform are good conductors of mechanical energy - otherwise known as vibration - so that this vibration can escape the component and be conducted into the platform, where it can be eliminated or conducted away.

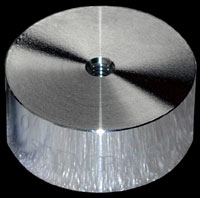

Because of the intrinsic design of Symposium Platforms, good mechanical coupling between chassis and the tops of our platforms is absolutely necessary for best results, because soft, compliant feet "break" mechanical transmission from the component into the platform and thus prevent proper resonance damping. In fact, soft footers actually intensify internal resonances by reflecting energy back into the component, compounding the problem we are trying to reduce or eliminate. Precision Couplers represent a logical evolution of Coupler technology for vibration control platforms, which was a concept first invented by Symposium in 1993 and introduced the following year with the first Super Platform. Precision Couplers are made from solid aluminum alloy. Aluminum is chosen over brass, steel, and other metals because of one primary characteristic: its ability to conduct mechanical energy. In nature, the ability of a material to conduct energy is known as its thermal transmission, and there is a "pecking order" in nature. The best metal conductor of energy is silver, followed by, in order, copper, then gold, and then aluminum. The first three metals, especially silver and gold, are impractical from a standpoint of cost and also mechanical hardness. copper is usable, but is also relatively expensive. Thus, aluminum becomes the logical choice for most applications needing good thermal transmission and machinability, and is superior to other metals such as brass and steel where sonic characteristics are concerned.

The Precision Couplers are made from a solid bar of 6061 aluminum, a premium alloy having strength, hardness, and good thermal characteristics. Each Precision Coupler is cut from a solid bar of 6061 aluminum and precision machined with highly finished surfaces; its opposing faces are nearly perfectly flat and parallel to ensure excellent coupling. Symposium presently offers three varieties of couplers: the standard Precision Coupler, described here, the Supercoupler, which is an upgraded version with superior 7075 alloy, a "Matrix" bottom of holes to improve coupling efficiency, and harder-than-steel "hardcoat" anodizing. Our best Coupler is the UltraCoupler, which is similar in design to the SuperCoupler but is made from pure, oxygen-free copper.

In order to provide best results, standard size and above Symposium Ultra and Super Plus Platforms, and all Quantum Signature platforms are supplied with some type of Coupler, since mechanical linkage from the component into the platform is an essential and primary feature of Symposium vibration control technology and methodology.

Svelte Speaker Sets, which come in pairs, are sold without couplers, because they should be used with the loudspeaker placed directly onto the Svelte's top surface. Precision Couplers are otherwise standard with standard size and larger Super Plus and Ultra Platforms, and are also available separately.

So what IS a "Coupler" - and what do I do with it?

The Coupler is a very simple device - and is supplied because it's important to make good mechanical contact to the chassis of your component. The reason for this is that mechanical energy "conducts" through materials analogously to electrical energy - that is, certain types of materials conduct mechanical energy (or vibration) well, and others don't. Examples of materials that conduct energy well are metals; a material that is a poor mechanical energy conductor is rubber. Usually, the denser the material, the better it can conduct energy. For instance, everyone knows that sounds underwater can be "heard" from great distances - greater distances than through air. This is due to water's superior density over air. Metals, because of their relatively high density, and also because of their atomic structure, are able to transfer energy with less loss than compliant materials. Thus, Couplers are made of high grade, "aircraft" aluminum alloys, with good transmission characteristics, or with oxygen-free copper in the top-grade UltraCoupler. In all cases, using three or four couplers under your equipment instead of simply placing your equipment down on its original feet provides significant advantages by mechanically connecting the component's chassis to the top layer or "plate" of the Symposium platform. In this way, the Symposium Platform becomes an extension of the component's metal chassis, providing a mechanical ground for energy to be drained off and dissipated without extraneous resonance or reflections back into the component.

The Coupler is a very simple device - and is supplied because it's important to make good mechanical contact to the chassis of your component. The reason for this is that mechanical energy "conducts" through materials analogously to electrical energy - that is, certain types of materials conduct mechanical energy (or vibration) well, and others don't. Examples of materials that conduct energy well are metals; a material that is a poor mechanical energy conductor is rubber. Usually, the denser the material, the better it can conduct energy. For instance, everyone knows that sounds underwater can be "heard" from great distances - greater distances than through air. This is due to water's superior density over air. Metals, because of their relatively high density, and also because of their atomic structure, are able to transfer energy with less loss than compliant materials. Thus, Couplers are made of high grade, "aircraft" aluminum alloys, with good transmission characteristics, or with oxygen-free copper in the top-grade UltraCoupler. In all cases, using three or four couplers under your equipment instead of simply placing your equipment down on its original feet provides significant advantages by mechanically connecting the component's chassis to the top layer or "plate" of the Symposium platform. In this way, the Symposium Platform becomes an extension of the component's metal chassis, providing a mechanical ground for energy to be drained off and dissipated without extraneous resonance or reflections back into the component.

Special notes about coupling the component

In general, we've found that the more contact with the chassis of the component, the better the results. Taken to its logical extreme, this would necessitate removing the original feet of the component - something which we don't advocate unless adequate ventilation can be preserved through the chassis, or in cases where ventilation isn't an issue (specifically, in components where the bottom of the chassis is sealed).

Placement

Placement

Where couplers are placed can have a considerable effect upon overall results. This is due to several factors, including the construction of the component's chassis bottom and location of protruding screws and other solid constructs linked to the interior of the component (which can be additional conduits for internal energy drainage). We have found that one should start with placement near the outer corner of the component, where the chassis is most rigid, and move the couplers in toward the center. In general, the best locations, as with Rollerblocks, seem to be approximately 1 to 3 inches in from any outside edges.

If your component's feet are too high

If your component has very high feet (more than 13/16" inches or 2 cm), the Precision Couplers will not touch the bottom of the chassis. Precision Couplers are made with a 1/4-20 threaded hole in one of their faces which allows two to be screwed together with a small 1/4-20 setscrew (available at any hardware store or from Symposium) in order to make one Double Precision Coupler of 1.625" (4.1 cm) in height.

If your component has very high feet (more than 13/16" inches or 2 cm), the Precision Couplers will not touch the bottom of the chassis. Precision Couplers are made with a 1/4-20 threaded hole in one of their faces which allows two to be screwed together with a small 1/4-20 setscrew (available at any hardware store or from Symposium) in order to make one Double Precision Coupler of 1.625" (4.1 cm) in height.